Advantages:

- Vertically integrated from mine to market - US based producer

- World class iron oxide resource with exceptional purity

- Producer of hematite, goethite & limonite for a range of colors and end use markets

- Ultra-low trace metal impurities

- Meets ASTM D85, D765, D3722 and D763 standards

- Strict in-house quality control laboratory

- Fine and ultra fine production capabilities

Applied Minerals is proud to introduce its AMIRON™ advanced natural iron oxides for a range of pigmentary and technical applications.

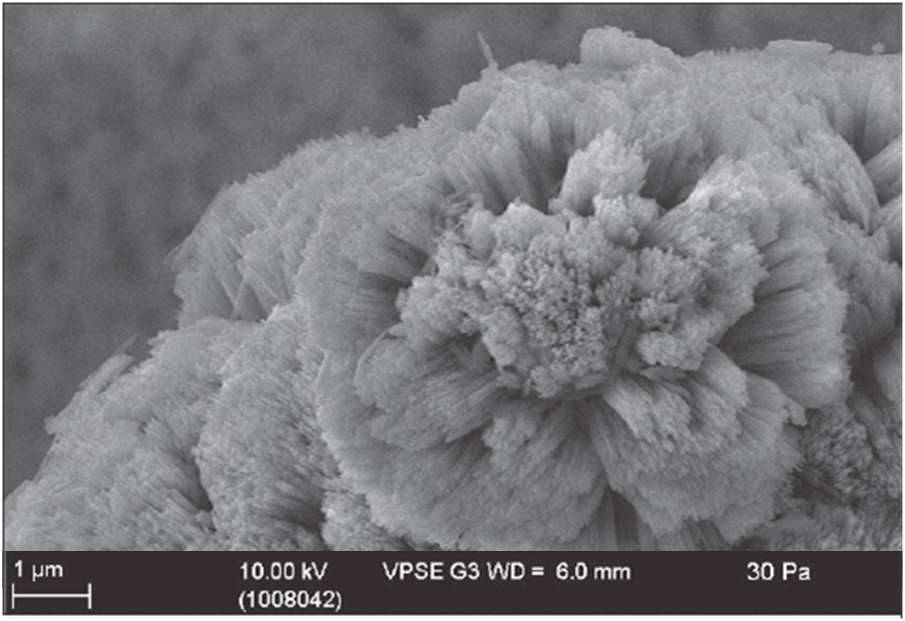

Vertically integrated from mine to market, Applied Minerals’ Dragon Mine property, located in Utah, USA, has been recently discovered to contain one of the purest in-situ resources of iron oxide in the world. The resource has been independently measured to contain over 3 million tons of iron oxide in the form of limonite, goethite and hematite, grading 95% on average. Chemically, the iron oxide contains exceptionally low levels of trace metal impurities, enabling its use in market applications that have traditionally been restricted to synthetically produced iron oxides.

Pigment Applications Technical Applications

LEARN MORE LEARN MORE

Applied Minerals’ production plant is commercially equipped with fine and ultra-fine milling technologies to produce a consistent range of the highest quality products from batch to batch. Its unrivaled commitment to product quality and consistency is further supported by a strong technical development team utilizing its onsite state of the art laboratory equipped with XRD, XRF, ICP-MS, sedigraph particle sizer, BET surface area, and Data Color color matching equipment.

With world class resources, production capabilities, quality control and the technical support to match, Applied Minerals’ mission is to become the industry's most reliable vertically integrated US source of advanced natural iron oxide products to the global marketplace.